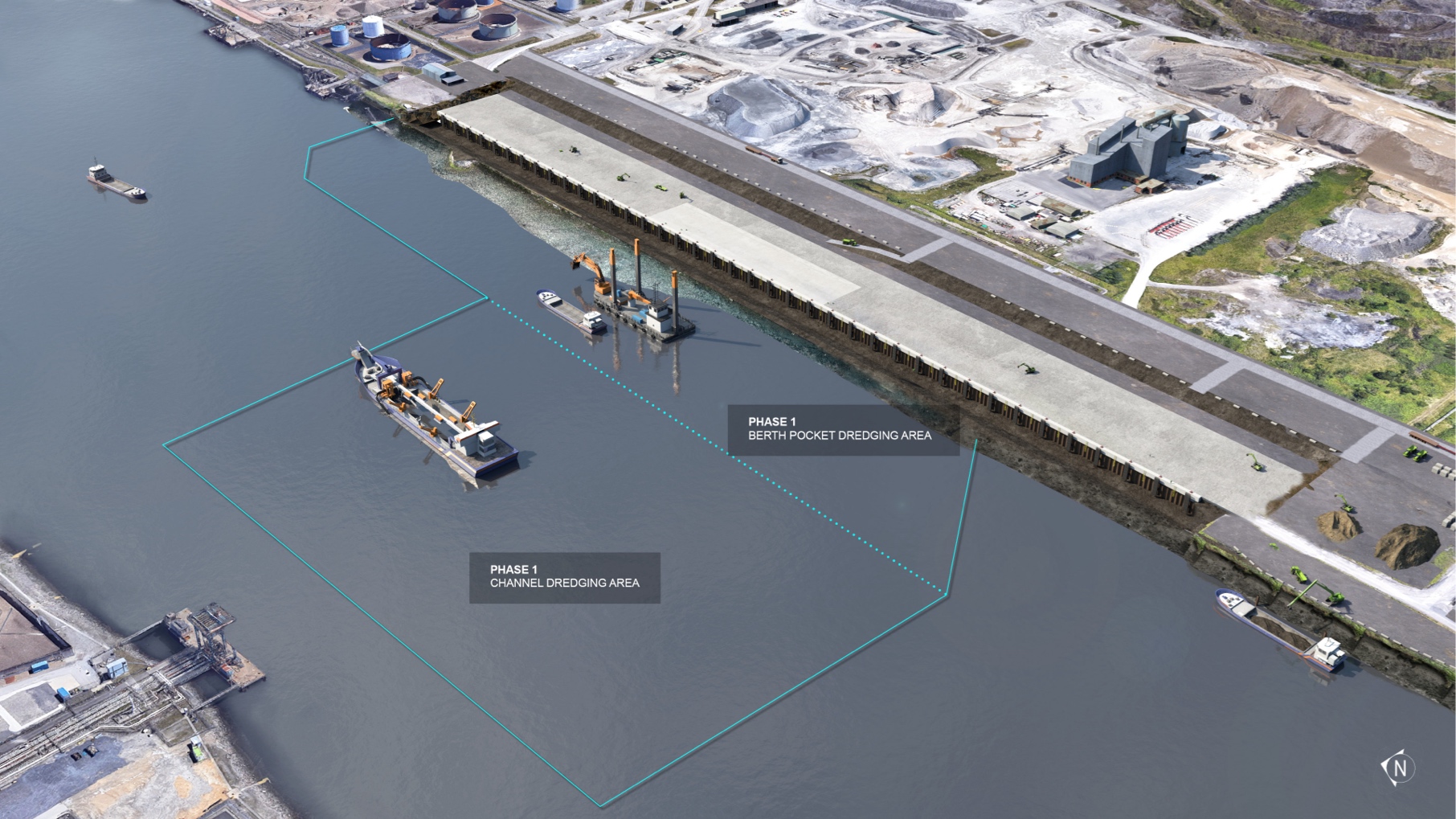

Project Brief – Graham’s secured the deep water regeneration project from clients Teessworks, to provide the first phase in an extensive regeneration program of the docklands in the Middlesbrough area. TCL were successfully appointed the piling package which included AZ sheet pile anchor wall and PU infill sheets to the front combi-wall as well as the placing and stressing of the anchor ties for the proposed new berthing platform. As the ground conditions in this area were particularly hard sub-contractor Bauer were engaged to core and install the 1829mm diameter steel tube king piles as part of the combi-wall with TCL to thread the 3No PU infill sheets once tubes were installed to depth.

Pre-augered pile line

Anchor Wall First Pile

16m AZ Sheets

Sheets sitting high

CX110 Impact Hammer

Anchor Wall - AZ 28-700 & AZ 42-700 installed using TCL ABI 16/20 into pre-augured pile line. Sheets refused high therefore were required to be impacted to depth using CX110 impact hammer once the full anchor wall line was fully pitched.

Combi-Wall Infill sheets – 3No PU22 sheet piles were to be installed between the large diameter king pile tubes. As the ground conditions were variable and harder than anticipated, these 3 gaps between the king piles where the PU sheet were to be installed had to be pre-drilled using a cased auger (by Bauer) in order that the sheets would pass to vibro refusal without damage. Sheets were installed using a small ground gate, crane mounted vibro hammer and a pencil impact hammer by Dawson so that the finished toe depth could be achieved.

Anchor ties and couplings

King piles and infill sheets

Waller beam and complete tensioning

Anchor Ties – Once the anchor wall was complete and the king pile tubes were installed, TCL then had to install 166No tensioned anchor ties which joined the front wall combi to the rear anchor wall. These anchor ties were then pre-stressed to take out the slack before being backfilled on the platform. They then received up to 4 additional passes with a torquing jack to achieve the required stress loadings.

Grahams installed steel waling beam across the back of the anchor and cast their concrete thrust block. TCL would then complete the stressing passes and record the data for submission to the clients engineer for approval.

TCL 16/20 Piling Rig

Proposed completed structure

Completion – Although the project is not due for completion until late 2023, TCL’s main remit to fulfil was the middle area of the berth “Heavy Lift Platform” that had to be complete by September 22. The remaining anchor ties were installed after and the regime of stress tensioning and loading of the structure continued for a further 7 weeks until complete and successfully handed over.

Pile logs for all elements of sheet install and anchor ties were submitted daily as many of the sheets required to be impacted to toe depth resulting in multiple visits to ensure finished heights were achieved. This added significant time to the overall contract that was originally provided of 5 months which ran to 9 months in total for full completion of the piling works.